As supply chain issues and labor shortages continue to plague manufacturers in all industries, many companies are rethinking their overall supply chain and manufacturing strategies.

Effects of Labor Shortage

The labor shortage has made keeping up with demand difficult which is in many cases especially acute around technology hubs and heavily industrialized areas. In response to this, some medical equipment companies have elected to have more content built externally. Where in the past many have outsourced fabricated and machined components, they are now having contract manufacturers (CM) build more highly integrated assemblies to feed their factories. While CMs are not immune to the tight labor market, they may be located in other geographic areas in the U.S. in which the problem is not as acute. They are also set up to more easily flex with the ups and downs of demand in the market.

Benefits of High-Level Assembly Outsourcing

Outsourcing of high-level assemblies (HLAs) can have many benefits. In addition to relieving some of the labor requirements for the OEM in-house, bringing in content in larger chunks can simplify the flow on the manufacturing floor, save space and take advantage of lower overhead than building up assemblies in-house. With fewer POs and suppliers to manage, the OEM’s supply chain personnel can focus on the most pressing supply chain issues.

Depending on the exact nature of the assemblies outsourced, electro-mechanical HLAs can also be functionally tested before arriving at the OEM’s factory floor. So, not only are fewer resources required to build the assemblies, but the time and personnel to perform test functions are no longer required. Some OEMs have elected to provide application-specific test protocols and equipment to their CMs so that HLAs can be provided in a highly integrated way directly to the factory floor.

Shifting Towards Domestic CM Reshoring

Where in the past it may have made sense for U.S. Medical Equipment OEMs to look to Asia for CMs there has been a shift towards more reshoring to domestic contract manufacturers. Many factors go into this calculation including high shipping costs, prohibitive lead times, IP exposure, continuity of supply risk, and quality issues. In many cases, these factors add up and point to a lower total cost when utilizing domestic CMs. Advanced CMs are able to compete globally utilizing labor-saving methods such as lights-out machining, robotic welding, and lean assembly and test methods.

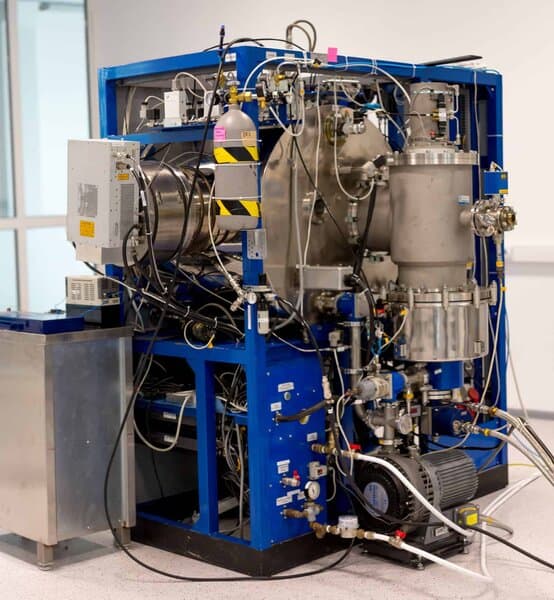

The opportunities to utilize domestic CMs are most pronounced for medical OEMs whose product is relatively large and complex. Imaging, radio-oncology, and medical robotics are a few examples where this strategy of outsourcing HLAs has proven very successful.

Partnering with the Right CM

When evaluating CMs, it’s important to find well-established companies who continually invest in technology and have experience in the medical capital equipment industry in general. These companies should have a proven management team, sophisticated supply chain management operations, and advanced internal manufacturing facilities.

You can count on Keller Technology as one of those companies. Learn about our mission, the wide range of industries we serve, and more about our experience as a medical contract manufacturer. Request a quote for your next project today.