Thank you for visiting the Keller Technology Corporation blog. We take pride in supporting companies with relevant industry information, so sometimes we cover topics outside of our services and capabilities. While surface treatments are necessary processes for virtually every system we manufacture, Keller Technology Corporation does not provide surface treatments as a standalone service.

- Engineers often specify an additional finishing treatment process for a portion, or all, of a metal part’s exterior surface.

- Some treatments provide enhanced mechanical or electrical properties.

- Processes include electroplating, chemical treatment, and hot dipping.

Why are metal surface treatments used for custom machinery parts? There are many benefits to using metal surface finishing in machinery parts. In an effort to prevent corrosion or simply improve appearance, engineers will often specify an additional finishing metal treatment process for a portion, or all, of a metal part’s exterior surface after it has been machined or fabricated.

In addition, some of these surface treatments in the custom machinery manufacturing process also provide enhanced mechanical or electrical properties that contribute to the overall functionality of the component.

Common Metal Surface Finishing Techniques Used

No matter what the reason, each of these eight metal surface finishing processes plays an important role in the custom machinery manufacturing process:

1. Electroplating – This process forms a thin metallic coating on the substrate. The electroplating process passes a positively-charged electrical current through a solution containing dissolved metal ions and a negatively charged electrical current through the metallic part to be plated. Common metals utilized for electroplating are cadmium, chromium, copper, gold, nickel, silver, tin, and zinc. Almost any base metal that conducts electricity can be electroplated to enhance its performance.

2. Electroless Plating – This metal surface treatment method is similar to electroplating; however, it does not utilize electricity. A reduction agent replaces the electricity, and it is contained in the plating solution.

3. Chemical Treatment – This method involves processes that create thin films of sulfide and oxide by means of a chemical reaction. Typical uses are for metal coloring, corrosion protection, and priming of surfaces to be painted. Black oxide is a very common surface treatment for steel parts and “passivation” is used to remove free iron from the surface of stainless steel parts.

4. Anodic Oxidation – This type of surface treatment is typically used for light metals, such as aluminum and titanium. These oxide films are formed by electrolysis, and since they are porous, dyeing and coloring agents are frequently specified for an improved aesthetic appearance. Anodization is a very common surface treatment that prevents corrosion on aluminum parts. If wear resistance is also desirable, engineers can specify a version of this method that forms a relatively thick, extremely hard, ceramic coating on the surface of the part.

5. Hot Dipping – This metal surface treatment requires the part to be dipped into dissolved tin, lead, zinc, aluminum, or solder to form a surface metallic film. Hot-dip galvanizing is the process of dipping steel into a vessel containing molten zinc. Used for corrosion resistance in extreme environments, guard rails on roads are commonly processed with this surface treatment.

6. Vacuum Plating – Vacuum vapor deposition, sputtering, ion plating, ion nitriding, and ion implantation are some of the more common metal surface finishing processes utilizing high vacuum as part of the plating process. Ionized metals, oxides, and nitrides are created in a controlled environment. The part is transferred into the vacuum chamber and the metals are very accurately deposited onto the substrate. Titanium nitride is a surface treatment that extends the life of high steel and carbide metal cutting tools.

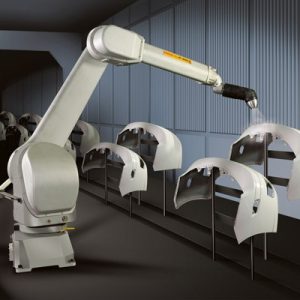

7. Painting – Surface treatment painting is commonly specified by engineers to enhance a part’s appearance and corrosion resistance. Spray painting, electrostatic painting, dipping, brushing, and powder coat painting methods are some of the most common techniques used to apply the paint to the surface of the component. There are many types of paint formulations to protect metal parts in a wide range of physical environments. The automotive industry has automated the process of painting cars and trucks, utilizing thousands of robot arms and producing extremely consistent results.

8. Thermal Spraying – This type of metal surface treatment involves melted or heated materials that are accelerated, then collided and bonded mechanically to the target surface. A wire or powder feedstock, usually metal or ceramic, is melted by injecting it into a flame, electrical arc, or plasma stream. Engineers sometimes specify this process when added friction is a desirable characteristic. It is also commonly used on larger structural objects for protection against high temperatures, such as a thermal barrier coating for exhaust heat management.

There are many other proprietary surface treatments and variants of the most common processes, which are engineered to improve or modify the characteristics of metallic parts. One example worth noting is a plastic impregnated ceramic coating that provides wear resistance and a slick, non-stick, surface, perfect for custom machinery components.

Learn More About Our Custom Machinery Manufacturing Services

Whether you work in robotics, semiconductors or the healthcare industry, Keller works with your team to design and engineer the equipment that you need. Does a component of your precision fabrication or custom machinery require specialized surface treatment technology? Let us know if you’d like more information about metal surface treatments for custom machinery parts.