- Industry 4.0, or Smart Manufacturing, will usher in a new approach to the production of goods.

- Customized output will result in the large-scale production of customized products and services.

- Assembly machines and automated systems will communicate potential problems to maintenance technicians before production is halted.

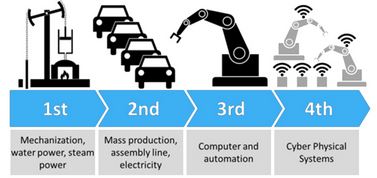

Industry 4.0, or Smart Manufacturing, and the Internet of Things (IoT) have promised manufacturers an incredible amount of data and level of connectivity in the near future. Highly intelligent machines, systems and components will be linked to create a fully digital value chain. The Fourth Industrial Revolution will be enabled by the industrial IoT.

Industry 4.0 will usher in a fundamentally new approach to the production of goods. The robots that produce products and the sensors that gather data will merge with artificial intelligence and connected networks to form a single, integrated system, encompassing both the physical and digital worlds.

Smart Manufacturing will take small-scale, customized output and combine it with modern manufacturing processes and technology. The result will be mass personalization; or in other words, the large-scale production of customized products and services. For example, products on an assembly line will receive communication from the factory’s machinery that dictates how they are to be individually processed. In addition, assembly machines and automated systems will communicate to maintenance technicians and notify them of potential problems before production is halted. Imagine sales, engineering, supply chain, manufacturing, and logistics – all smart and all connected.

The benefits of this type of manufacturing are clear. Consumers get highly personalized goods at affordable prices, while industry gets increased efficiencies and flexible production that can adapt to rapidly changing markets.

But won’t all of this connectivity expose corporate IP and increase our vulnerability to hacking? While no system is perfectly secure, the Smart Factory’s defining quality is intelligence. The advanced software of Industry 4.0 and the IoT will anticipate threats and manage problems in real time. This level of network security will allow us to enjoy the benefits of the Fourth Industrial Revolution while managing the risk.

Technology still has a way to go, but it’s just a matter of time before a passenger in a car, an engineer in his lab and the smart robotic systems in the factories of the future will be connected in ways that seem unimaginable today. The pace of technological development has never been faster and we are excited to see what the future holds. Contact Keller Technology Corporation to learn more about industry’s newest sensing, machine control and communication technologies.