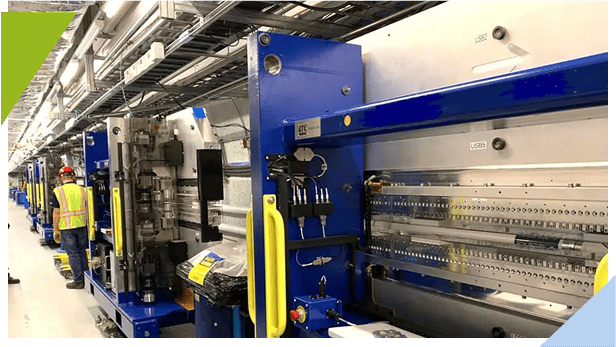

Custom Precision Fabrication

Keller Technology excels in serial production services for equipment OEM’s as well as low quantities for custom machinery and research applications. Our build-to-print fabrication services cater to a diverse range of industries, ensuring adherence to customer specifications, while maintaining stringent ISO 9001 certification standards. Whether you require fabrication with standard or specialty materials, Keller delivers the tailor-made precision fabrication solutions you need.

Precision Fabrication Overview Video

Precision Fabrication Case Study

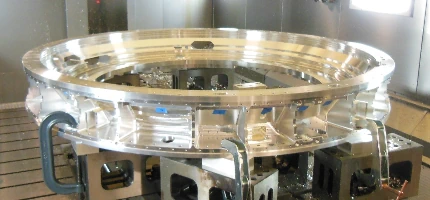

Undulators are a key component within photon systems in XFEL’s and synchrotrons. This case study examines a build-to-print project undertaken by our company to machine, fabricate, assemble and integrate a series of undulators for a prominent government laboratory.

Our precision fabrication capabilities

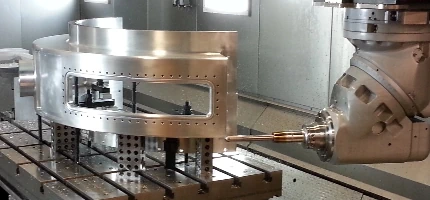

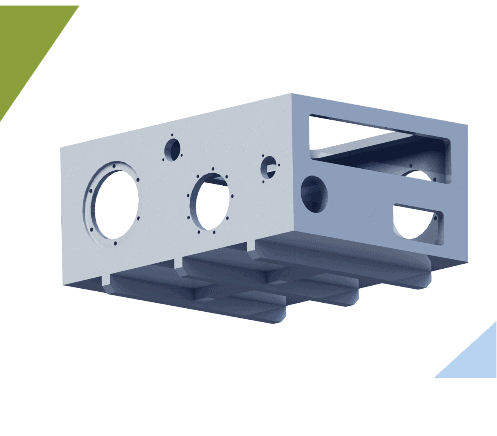

We specialize in high-end equipment for quality critical applications, including value-added integrations of vacuum chambers with frames, internals, electro-mechanics, pneumatics, load-locks and robotics as well as custom mixers, undulators, accelerator and cyclotron components and other custom-built hardware for leading research facilities.

Our expertise encompasses large-envelope 5-Axis machining, advanced welding, and comprehensive precision machine and fabrication capabilities. Complementary services include hand grid, polish and cleaning for UHV applications. With the support of our cutting-edge machine shop, certified welding professionals, and experienced assembly technicians, Keller’s custom precision fabrication capabilities play a pivotal role in sectors ranging from energy research, semiconductor manufacturing equipment, healthcare to national defense.

Using customer-supplied drawings, our advanced machining and fabrication capabilities ensure your highly specialized assemblies meet all necessary requirements.

We specialize in the production of stainless steel and aluminum vacuum chambers with large, complex geometries.

KTC can design, fabricate, test, document and stamp in accordance with ASME section VIII, division 1 code pressure vessels, in stainless steel, carbon steel and other materials.

KTC’s machining and fabrication solutions are ideal for manufacturing vacuum chambers, and our clean room capabilities are well suited for high-level assemblies (HLAs).

KTC has the personnel, skills and facilities to handle a wide variety of large-envelope precision fabrication projects.

KTC manufacturers particle accelerator and cyclotron equipment for research, oncology, medical imaging and homeland security.

Our state-of-the-art machine shop features a variety of fabrication tools including several 5-axis machine tools.

KTC specializes in high-end, complex fabrications for the healthcare capital equipment industry.

Keller routinely manufactures precision equipment requiring expertise in the cGMP regulatory environment

Value-add services and support

Related resources

Certified for quality

For every project that comes through our facilities, KTC is committed to excellence. We have a dedicated quality control system with documented standards and procedures, and we comply with strict quality standards.

Ready to work with us?

Contact the team at KTC to quote your next precision fabrication project. We look forward to partnering with you.