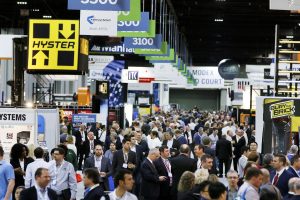

- More than 900 exhibitors from around the world and 30,000 guests attended MODEX 2018.

- Several exhibitors featured cutting-edge six-axis robots picking and sorting products utilizing sophisticated machine vision and AI.

- Demonstrations featured automated picking systems and heavy-duty autonomous robots.

Innovative robotics solutions dominated MODEX 2018, which lived up to its motto of “The Greatest Supply Chain Show on Earth,” April 9-12th at the Georgia World Congress Center in Atlanta, GA. More than 900 exhibitors from around the world and 30,000 guests, including representatives from Keller Technology Corporation (KTC), discussed the latest supply chain, material handling, sortation and warehouse automation technologies. The 2018 version of the show also expanded to two buildings totaling 280,000 square feet.

Attendees hit the ground running, with several exhibitors noting the brisk pace of those actively seeking specific products and technologies. You know you’re having a good show when you need your office to send you more business cards mid-week.

While many companies showed standard warehouse racks, handling carts, fork trucks, urethane-coated wheels, stretch wrappers and carton taping machines, numerous exhibitors featured cutting-edge six-axis robots picking and sorting products utilizing sophisticated machine vision and artificial intelligence.

The Soft Robotics demonstration of its SuperPick system, had a crowd of impressed onlookers asking questions. The automated picking system used web cameras and a Fanuc LR Mate robot to pick random objects from bins.

The Soft Robotics booth was also the interactive highlight of the day, allowing attendees to grasp a variety of objects with the company’s innovative gripper. The unit’s air-filled fingers open and close using compressed air and vacuum that is supplied by a control unit. This unique end of arm tooling design allows the gripper’s malleable rubber fingers to grasp and pick up objects of almost any shape and density.

Bleum Robotics introduced its first two robot models at the 2018 MODEX show. Designed for use in automated warehouses without the presence of humans, these heavy-duty autonomous robots lift an entire shelf of products and quickly transport it out of the warehouse and into a safe area where speeds are reduced. Once stopped, employees can safely complete their designated tasks.

Also well-represented at MODEX were Autonomous Mobile Robots (AMRs), which are deployed in warehouses and distribution centers and work safely alongside humans. The Fetch Robotics booth drew the largest crowd of onlookers, who listened to company CEO Melonee Wise share the benefits of these robots in real-world use – while wearing her trademark Chuck Taylor All-Star high tops, of course.

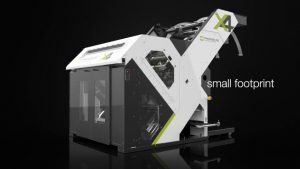

The Packsize booth showcased another impressive piece of equipment, which was also one of the most complex. The recently introduced X4 machine was making “on demand” shipping boxes from a ribbon of corrugated material.

The X4 can cut, fold, label, and glue a flat corrugated box in 12 seconds. It was fun to watch and listen to this machine as it made a box that was exactly the right size for the job.

Innovative companies, both small and large, are using creative thinking and cutting edge technology to solve long standing staffing and efficiency problems. As a result of these advancements, automation is rapidly expanding into restaurants, warehouses, distribution centers and farms, and changing the way companies do business. Keller Technology Corporation embraces this change and continues to help our OEM customers achieve their goals by providing cutting edge solutions to their most challenging contract manufacturing problems.