- Keller Technology has played a key role in the production of SXR and HXR undulators for an LCLS-II free-electron laser.

- Keller Technology has been involved with the LCLS-II program at Lawrence Berkeley National Lab (LBNL) for the past five years.

- Keller Technology has manufactured the mechanical systems, frames and strong backs, as well as integrating, aligning and measuring extremely powerful rare earth magnets to micron level accuracy to create complete undulators.

When the SLAC National Accelerator Laboratory in Menlo Park, California, finishes building the LCLS-II free-electron laser, a whole new world of scientific discovery will be opened up to researchers. Keller Technology Corporation has had the priviledge of playing a key role in the production of SXR and HXR undulators used in the project.

A joint partnership of the SLAC and four other Department of Energy national laboratories, including Argonne National Laboratory, Berkeley Lab, Fermilab, and Jefferson Lab., the second version of the Linac Coherent Light Source will allow lab scientists to:

- Take crisp pictures of atomic motions

- Watch chemical reactions unfold

- Probe the properties of materials

- Explore fundamental processes in living things

The LCLS-II will bring with it the ability to perform experiments in a wide range of fields previously thought impossible. According to SLAC, the new X-ray laser will move from the original version’s 120 pulses per second to 1 million, allowing for discoveries to advance technology, new energy solutions and quality of life.

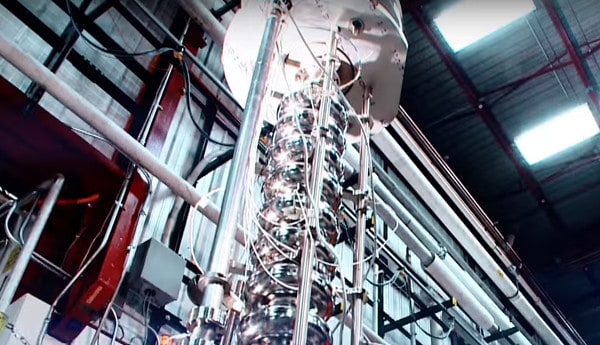

Despite the dramatic boost in capability, both the original version and the LCLS-II work by using electrons accelerated to nearly the speed of light to generate beams of extremely bright X-ray laser light. The electrons travel through a series of magnets, called an undulator, which forces them to travel a zigzag path and give off energy in the form of X-rays.

Keller Technology has been involved with the LCLS-II program at Lawrence Berkeley National Lab (LBNL) for the past five years, manufacturing the mechanical systems, frames and strong backs, as well as integrating, aligning and measuring extremely powerful rare earth magnets to micron level accuracy to create complete undulators.

In 2013, Keller Technology delivered the prototype SXR (soft X-ray) undulator unit to LBNL, followed by the pre-production unit in July 2016. Successful completion of these activities positioned Keller Technology for a production phase of the program. Since the initial delivery in 2016, Keller Technology has completed 22 SXR mechanical systems along with completing magnet integration, control systems, acceptance testing and delivery of ten production undulators.

“Keller Technology is proud to partner with the DOE’s National Laboratories to advance science and contribute to the development of transformative technologies,” said Barnaby Keller, Vice President Business Development. “Highly complex electromechanical systems and precision instrumentation fit well with Keller Technology’s vertically integrated capabilities that include precision welding/fabrication, five-axis machining, assembly, integration, metrology and testing.”

LBNL also partnered with Keller Technology to produce equipment for the pre-production HGVPU (horizontal gap vertically polarizing undulator) assembled at LBNL in 2017. Keller Technology began production of 17 HGVPUs in January of 2017. Building from experience gained on the SXR undulator program, Keller Technology completed and delivered the first production HGVPU in October 2017.