- Clean room assembly requires strict adherence to SOPs.

- On-time manufacturing project delivery requires a detailed process developed by experienced engineers.

- High-level assembly requires periodic testing through the project.

When selecting a contract manufacturer for your precision assembly, you need to be confident in the company’s ability to maintain high standards for controlled environments. Expertise with clean room assembly, electro-mechanical assembly, and high-level assembly require meeting the unique requirements for each.

Precision Assembly Focus: Controlled Environments

Clean room assembly calls for strict adherence to Standard Operating Procedures, or SOPs. These detailed guidelines govern training, gowning procedures, room air quality, record-keeping, and general work conditions.

Successful manufacturing for industries such as semiconductor, nanotechnology, and medical research depends on following not just some of these rules, but each and every one. While the gowning process may seem simple, failing to skip even one step can result in contamination of the sterile environment.

Keller Technology Corporation goes to great lengths to ensure the proper environment for all precision assembly performed in a clean room environment, meeting all ISO 7 level standards.

Precision Assembly: Electro-Mechanical Assembly

Electro-mechanical assembly begins with your blueprints or our design team developing your product specifications. Throughout the process, you should be able to rely on your contract manufacturer of choice to keep the project on track, while also adapting to necessary changes along the way.

Keller Technology relies on a wealth of experience with projects of this complexity. Our engineering team uses their in-depth experience with these types of precision assemblies to develop the manufacturing process and deliver your product on-time and at budget.

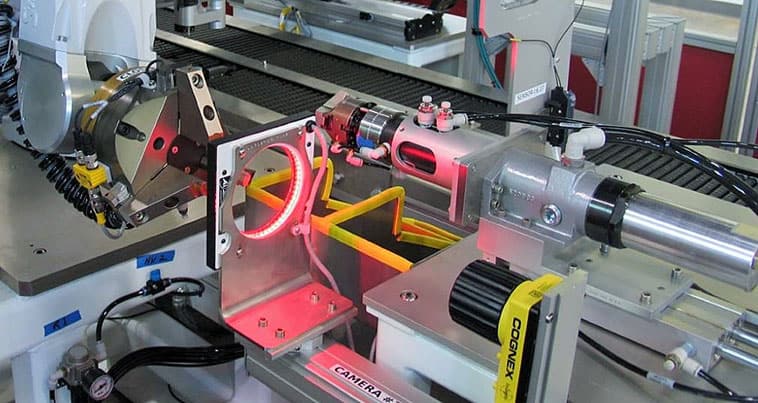

Precision Assembly: High-Level Assembly

High-level assembly provides precision assemblies just short of turnkey systems, resulting in a finished product more integrated than an electro-mechanical assembly. You should feel confident that your design will be translated by the contract manufacturer into the HLA solution you need, when you need it.

Precision assembly of this type must include testing, and Keller Technology accomplishes this task at critical stages in the design and built process. Our engineering team also can integrate your proprietary technology for a true custom manufacturing solution.

Solutions for contract manufacturing

From supply chain management to product development to JIT shipments, Keller Technology Corporation has the experienced manufacturing and engineering teams to handle the complexity of your contract manufacturing project. Learn about the types of industries we’ve served.