Build-to-Print Manufacturing for Custom Machinery

- Builds are executed according to detailed manufacturing plans

- Build-to-print manufacturing processes adhere to strict quality standards and industry regulations

- Projects are tracked and milestones shared with the customer regularly

Keller’s technical experience and comprehensive support ensures your build-to-print success

Frequently, build-to-print manufacturing projects require additional support services to ensure success. KTC’s well-seasoned engineers, program managers, and sourcing and technical staff review all customer designs and documentation for completeness, part obsolescence issues, design for manufacturability, and cost-effectiveness.

We are experienced custom machine manufacturers who work in complex, highly technical and specialized manufacturing industries, including aerospace, defense, pharmaceuticals and energy, KTC has the capability to create the machinery your application requires, including robotics integration or high-speed web-based equipment, depending on your application’s needs. Keller Technology also supplies build-to-print manufacturing services to the life sciences/healthcare, consumer products and building products industries.

ISO Certified and Clean-Room Capable

When your projects require precision adherence to stringent controls, trust Keller Technology’s multiple nationally-certified facilities. Our Buffalo, NY, location is ISO-9001 certified and our Charlotte, NC, location is certified in both ISO-9001 and ISO-13485. We offer controlled environment capabilities and ITAR compliance, as well.

Buffalo, New York

Charlotte, North Carolina

Work with Keller

Whether your project requires hard or flexible automation; web handling, forming or converting; or process equipment, KTC delivers reliably and on-time. Optimized supply chain management and internal operations allow for multiple unit builds.

Outsourcing the manufacturing of your sub-assembly or machinery to a contract manufacturer is serious business. KTC is the manufacturer of choice for some of the world’s largest manufacturing companies, each with distinct power, regulatory and safety requirements.

When your reputation is at stake, trust the experience of Keller Technology to bring in your build-to-print manufacturing project on time and within budget.

Build-to-print project profiles

Build-to-print manufacturing frequently asked questions (FAQs)

The majority of build-to-print projects we complete begin with documentation packages that are lacking or indicate commercial items that are now obsolete. It is standard practice for Keller to thoroughly review all materials for potential issues prior to the start of a project.

Keller has the capability and resources to take your proof-of-principal or prototype design to completion – including DFM – and deliver a world-class documentation package that is ready for manufacturing.

Build-to-Print Solutions for Custom Machinery

Vacuum Deposition

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Description of project profile: Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur suscipit cursus enim, quis malesuada nisi mollis vitae. Vestibulum ac tempor tortor. Proin non justo et metus tristique consequat cursus rutrum ex. Quisque posuere a orci a porta. Integer tellus neque, sodales a urna semper, congue tempor purus.

Services

- Project Management

- Engineering Support

- Machining

- Fabrication

Highlights

- Faster removal of material with each tool pass

- Fewer setups to machine complex geometries

- Better surface finishes when machining contours

- Reduction of fixturing tooling

Custom vacuum chambers project profiles

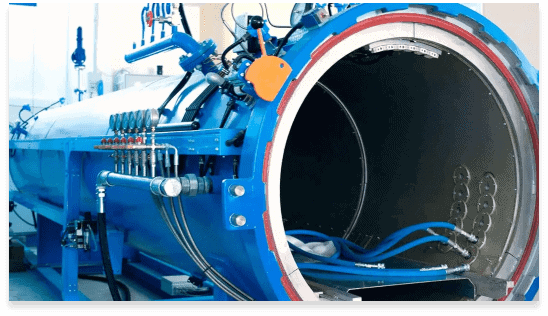

Custom vacuum chambers

Integrated vacuum chamber system

Integrated cylindrical and box type chambers.