Build-to-Print Solutions for Contract Manufacturing

Keller Technology Corporation (KTC) offers specialized build-to-print contract manufacturing services for complex machinery and equipment. Our team of experienced technicians, engineers, and project managers transforms your designs into high-performance products, providing advanced solutions to your most challenging projects.

- ISO-Certified & Clean Room Capabilities: ISO 9001 and ISO 13485 certifications, along with controlled environment rooms, ensure the highest quality standards. Adherence to Rigorous Industry Standards: We maintain strict compliance with your industry regulations and quality controls. High-Level Assemblies (HLA) to Turnkey Systems: KTC seamlessly becomes your manufacturing partner.

End-to-End Support for Optimized Results

Our engineers thoroughly review all customer designs prior to manufacturing, identifying opportunities to enhance efficiency and streamline production. With a volume-leveraged supply chain, we optimize material procurement, address part obsolescence, and manage logistics to ensure smooth, cost-effective operations.

Expertise Across High-Tech Industries

KTC specializes in contract manufacturing for demanding quality-critical industries, including:

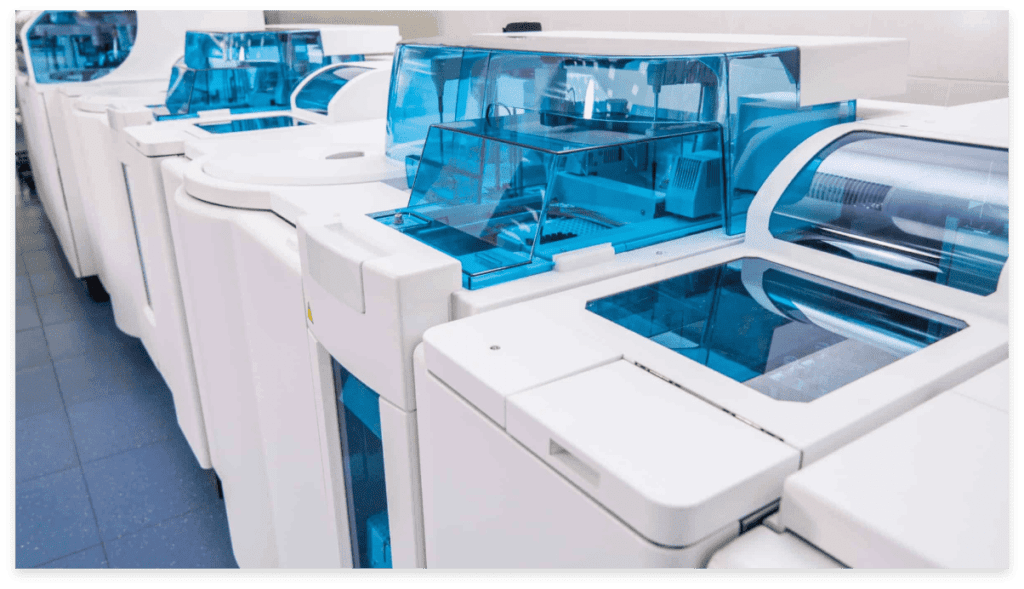

- Medical Diagnostics and Life Sciences: Precision manufacturing for reliable, high- performance diagnostic and life sciences equipment.

- Semiconductor and Nanotechnology: Advanced fabrication with stringent precision and contamination control for cutting-edge applications.

- Defense and Aerospace: High-accuracy solutions built to withstand the rigorous demands of defense and aerospace applications.

- Packaging and Industrial: Sophisticated build-to-prin

Certified Compliance You Can Trust

Our Buffalo, NY, facility is ISO-9001 certified, and our Charlotte, NC, location holds both ISO-9001 and ISO-13485 certifications, with ITAR compliance and clean room assembly and integration capabilities at both locations.

Buffalo, New York

Charlotte, North Carolina

Work with Keller

Contracting with KTC for your build-to-print manufacturing provides sophisticated solutions to complex challenges, including precision and accuracy at volume. Whether your application requires repeating quantities, integrated automation, controlled environments, or all of the above, trust the team at Keller to execute an optimized build that surpasses your expectations.

Build-to-print manufacturing project profiles

Build-to-print frequently asked questions (FAQs)

Every project begins with a standard review of all existing designs and documentation, to identify outdated commercial parts and other manufacturing issues. We’ll review your project for potential issues thoroughly before we start and communicate with you every step of the way.

KTC’s engineering team has the resources and ability to complete the DFM process using your prototype design, producing a comprehensive documentation package ready for manufacturing.

Partner with Keller Technology

When you partner with Keller Technology Corporation for build-to-print manufacturing, you gain sophisticated solutions tailored to complex challenges, with precision, volume capabilities, and automated processes to meet your exact requirements.

Contact us today to learn more about how KTC can bring your designs to life with unmatched quality and precision.