In the world of manufacturing, precision and innovation go hand in hand. As industries like aerospace, energy, medical, and semiconductor manufacturing demand increasingly complex and high-performance components, staying ahead requires more than just expertise—it demands continuous investment in advanced technologies. Among the most transformative advancements in machining are state-of-the-art 5-axis machine tools, which are revolutionizing how large, precision components are created.

At Keller Technology Corporation, we are committed to delivering unmatched precision and performance by continuously investing in cutting-edge machine tools, ensuring our customers benefit from the latest capabilities. Let’s explore what makes 5-axis machining so groundbreaking and how it supports the production of complex, large-scale components.

5 Capabilities of 5-Axis Machining

Unparalleled Precision and Accuracy

Advanced 5-axis machines are equipped with cutting-edge control systems and feedback technologies that deliver exceptional precision, even for large and intricate components. Maintaining tight tolerances over large dimensions is a challenge that these machines meet with ease, making them indispensable for industries where accuracy is critical.

Efficiency Through Fewer Setups

One of the most significant advantages of 5-axis machining is the ability to perform complex operations in a single setup. Traditional methods often require multiple setups to achieve the desired geometry, increasing the risk of misalignments and errors. With 5-axis machining, efficiency is greatly improved, reducing production time and costs.

Machining Large Components with Precision

Many 5-axis machines are specifically designed to handle large-scale workpieces. These machines feature expansive work envelopes, robust structures, and high-capacity rotary tables capable of supporting heavy components. This capability allows us to manufacture large parts like turbine blades, aerospace structures, and industrial molds with precision and repeatability.

With our continuous investment in modern, large-capacity 5-axis tools, we’re uniquely positioned to tackle even the most complex large-scale projects. This commitment to upgrading and expanding our capabilities ensures that we remain a trusted partner for industries with high-precision requirements.

Enhanced Capabilities for Complex Geometries

The additional axes of rotation in 5-axis machines allow for the creation of intricate contours, undercuts, and compound angles that would be impossible with traditional 3-axis machining. These machines are ideal for manufacturing components with highly complex geometries, ensuring that the end product meets the most demanding performance requirements.

Our ability to approach the workpiece from virtually any angle minimizes the need for secondary operations, resulting in superior surface finishes and reduced manual intervention. This is a crucial advantage for parts that require both functional and aesthetic precision.

Multi-Pallet Systems for Increased Throughput

Modern 5-axis machines with multi-pallet systems are a game-changer for boosting productivity. These advanced systems allow for the setup of multiple projects or workpieces at once, ensuring minimal downtime between machining operations. This capability streamlines workflows and enables us to maintain high throughput even when handling multiple customer projects simultaneously.

With multi-pallet systems, we can achieve higher efficiency, reduce setup times, and improve overall production speed through lights-out manufacturing – all while maintaining the superior quality that our customers have come to expect.

Our Latest Machine Tool Additions

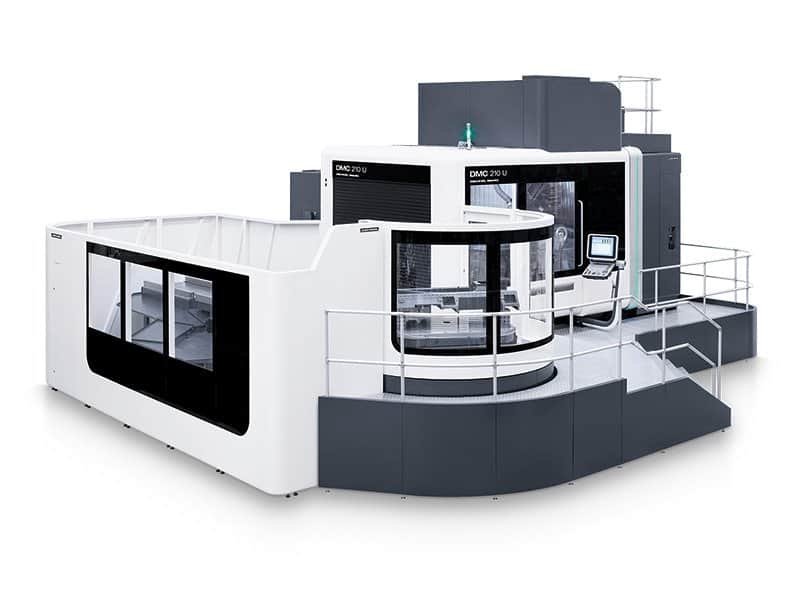

Our commitment to staying on the cutting edge of machining technology is exemplified by our recent additions to our fleet. Below is a chart showcasing the three most recent machine tools we’ve added, each enhancing our ability to serve customers with greater precision and productivity:

Machine Tool Model Capabilities

DMG/MORI DMC210FD Large work envelope, 5-axis milling w/vertical turning, 2 pallets

DMG/MORI DMC210U Large work envelope, 5-axis, 5 pallets

DMG/MORI DMC160U Medium work envelope, 5-axis, Micro Precision, 2 pallets

Investing for Our Customers

State-of-the-art 5-axis machine tools are transforming the manufacturing landscape, enabling the production of large, precision components with exceptional accuracy, efficiency, and complexity. By continuously investing in cutting-edge equipment, Keller Technology Corporation ensures that our customers benefit from the most advanced machining capabilities available.

Whether you need intricate aerospace components, high-performance energy system parts, or precision medical equipment, Keller Technology Corporation is your trusted partner for achieving excellence in 5-axis machining. Contact us today to learn more about how our investment in advanced technologies can support your next project.