- Five-axis machining allows for the elimination of wasteful set-ups.

- Keller Technology machining centers provide high-speed, large-envelope capabilities, as well as automatic pallet changing.

- Our machining capabilities include aluminum, stainless steel, cold- and hot-rolled steel, exotics, high nickel and super alloys.

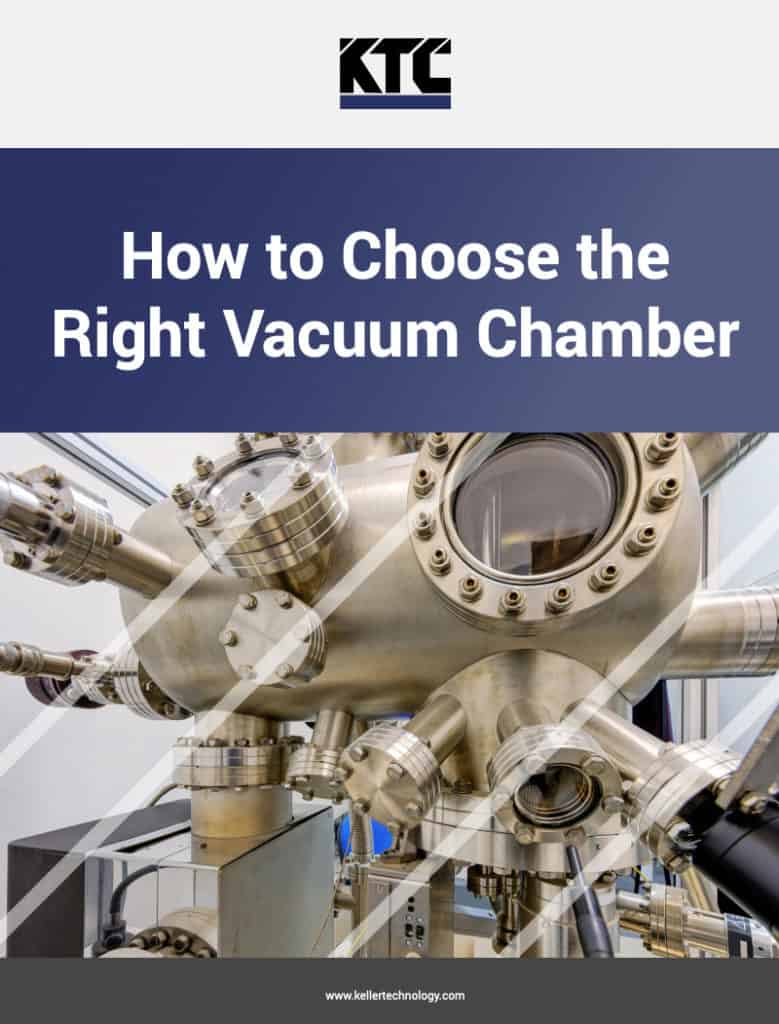

Manufacturing large, complex parts for the semiconductor, medical device and engineered materials sectors can be costly. As a supplier of manufacturing services for the production of complex electro-mechanical machinery, process equipment and instruments, much of the cost of what we produce lies in these large machined and fabricated components.

But what if you could produce these parts – vacuum chambers, and machined housings or forgings – more efficiently?

That’s exactly why Keller Technology Corporation has become an innovator in five-axis machining for global markets where expert application of this technology is critical. It allows for the elimination of wasteful set-ups, while also providing a multitude of possibilities for attacking the manufacturing of a part or feature.

We have developed expertise in optimizing this technology to determine the most efficient way to execute large, complex parts. Since the market is so competitive and fast moving, constant investment in machine tools and hardware is necessary to establish and maintain the advantage.

Keller Technology has invested in several five-axis machining centers to be able to provide high-speed, large-envelope capability, as well as automatic pallet changing for production runs and lights out machining. Our largest five-axis machine tool features an envelope of X=236”, Y=118”, Z=59”. Investments have also been made in software to help maximize the capability of our machine tools. To improve speed and efficiency, we utilize VERICUT, Mastercam, and SpaceClaim software.

Our capabilities in the fabrication and machining of aluminum, stainless steel, cold- and hot-rolled steel, exotics, high nickel, and super alloys, coupled with our assembly, integration, and engineering experience, make us the ideal partner for custom or production equipment, machinery, or instrumentation.

See our five-axis machining capabilities in action in the video below.